Our Pre-engineered Cleanroom Systems

Superior Fit and Finish Ensures an

Air-tight Environment

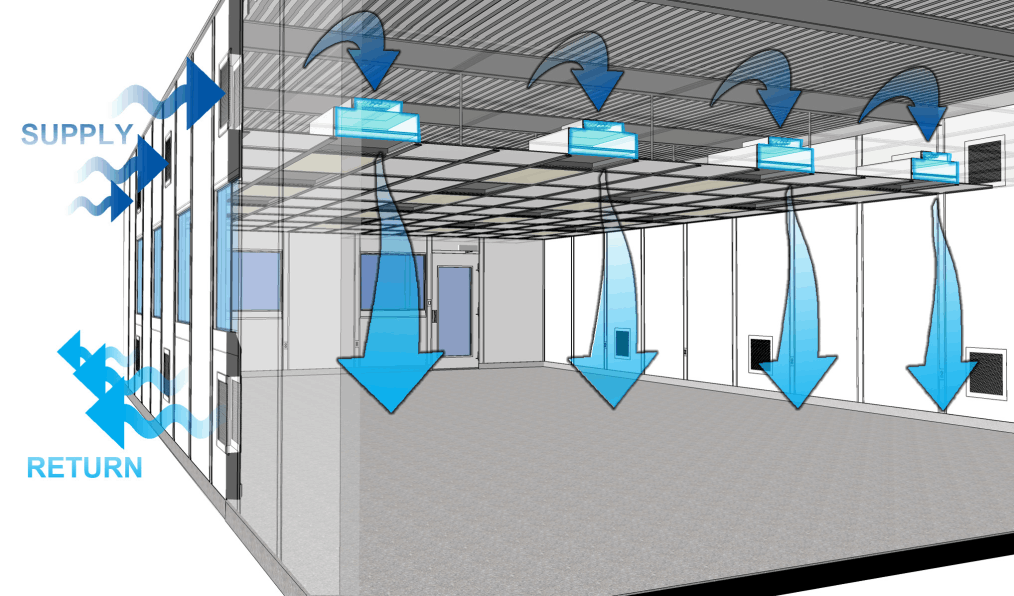

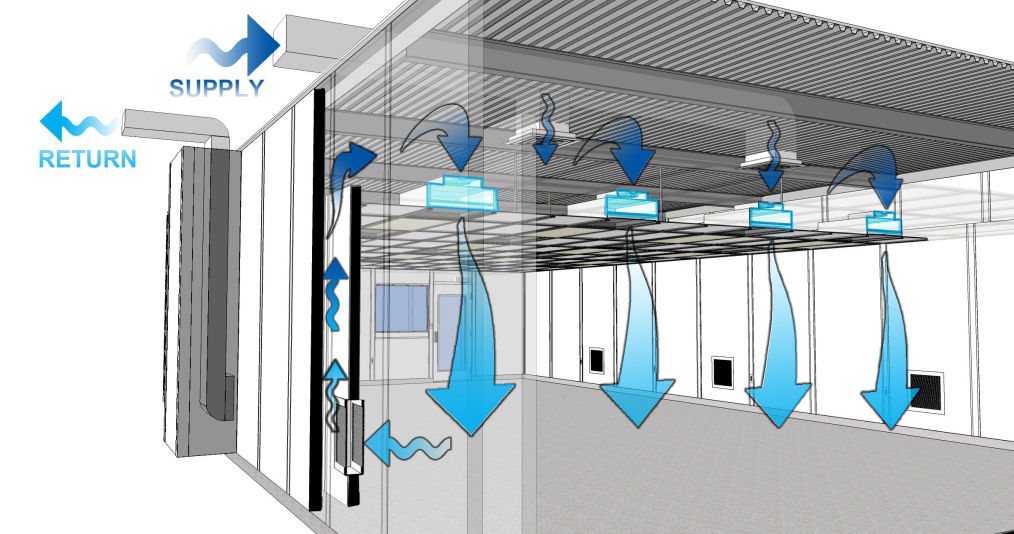

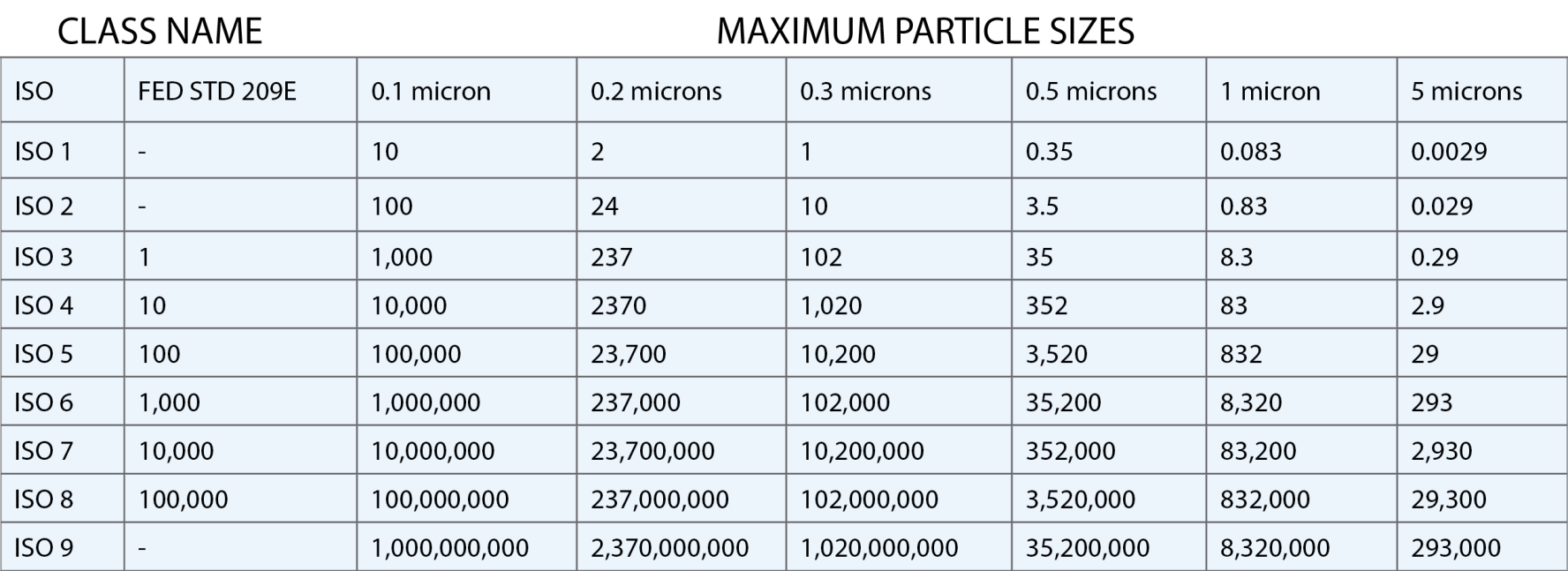

Our pre-engineered cleanroom systems are custom designed and built with precise tolerances to meet your specific needs and classification requirements.

We have interfacing walls, floors, and ceilings with smooth edges, accurate cuts, and precisely mitered joints. This precision engineering ensures a tight, air-leak proof construction and assembly that facilitates air particle filtration, and the control of air flow, pressure, temperature and humidity.

Our cleanroom interior surfaces and air plenums are made from non-particulate shedding materials such as vinyl, fiberglass, and pre-finished aluminum.